How you protect your grain from fungi and pests

The infestation of the grain with pests and the development of secondary fungi must be prevented. It is therefore all the more important to create suboptimal conditions for insect pests and moulds during storage, thereby reducing the risk of spoiling of the grain to a minimum.

Prevention in preparation for storage

Grain protection starts even before storage. The grain store should be completely emptied and cleaned thoroughly. Corners, joints and crevices in particular create survival spaces for insects. Pests can survive under old grain and dust, and in cracks and holes. Such potential refuges should therefore be cleaned or eliminated.

The conveying equipment should also be cleaned and function properly so as not to damage the conveyed bulk. For grain beetles and other species that cannot feed on intact grain, broken grains are an easy meal. The cleaning of the warehouse with pesticides must be carried out in accordance with regulations and must be strictly documented. Constructional measures such as securing exhaust air holes with meshes or grilles help keep birds and rodents away from the grain. Bought-in grain should be checked carefully before transfer to stores.

Fungi endanger cereals, humans and animals

Field fungi (primary fungi) are introduced to the store with the harvest and it is from the primary fungi that the storage fungi (secondary fungi) develop. Under favourable conditions, these moulds produce highly toxic mycotoxins that endanger human and animal health. In pigs, for example, they cause reduced appetite, reduced growth and fertility problems. Highly contaminated feed can kill farm animals. The EU therefore prescribes strict limit values for mycotoxins.

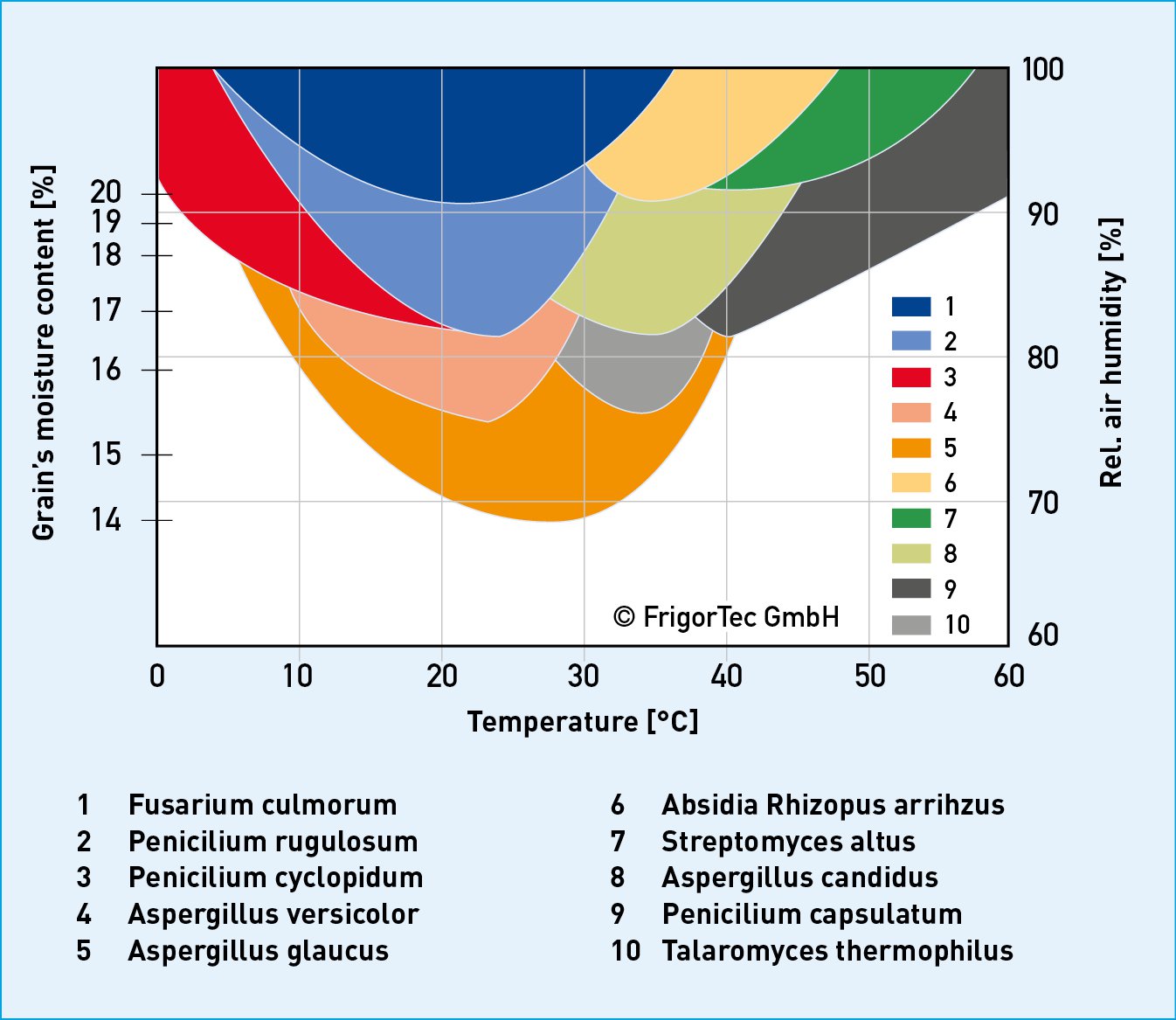

Heat and moisture stimulate the metabolism of moulds and promote the formation of mycotoxins. If the crop remains uncooled, the fungi find ideal growing conditions.

Growth of various organisms dependent on moisture and temperature

Insect infestation is often discovered too late

Insect infestation can significantly damage stored grain. Eating, excrement and the rapid reproduction of many pests lead to loss of substance and deterioration in quality.

Insects often spread inconspicuously in the loose grain. In many cases, an infestation with grain beetles, for example, only becomes apparent when there is a mass hatching of new beetles. Since the grain beetle has a generation cycle of only 25 days under optimal conditions, by the time it is notice it may already be too late. Grain beetles lay an egg every day, so they can be present in the affected cereals at any stage of development. Pesticide control only kills developed beetles. Eggs, larvae and pupae lodge in sealed grains where they are protected.

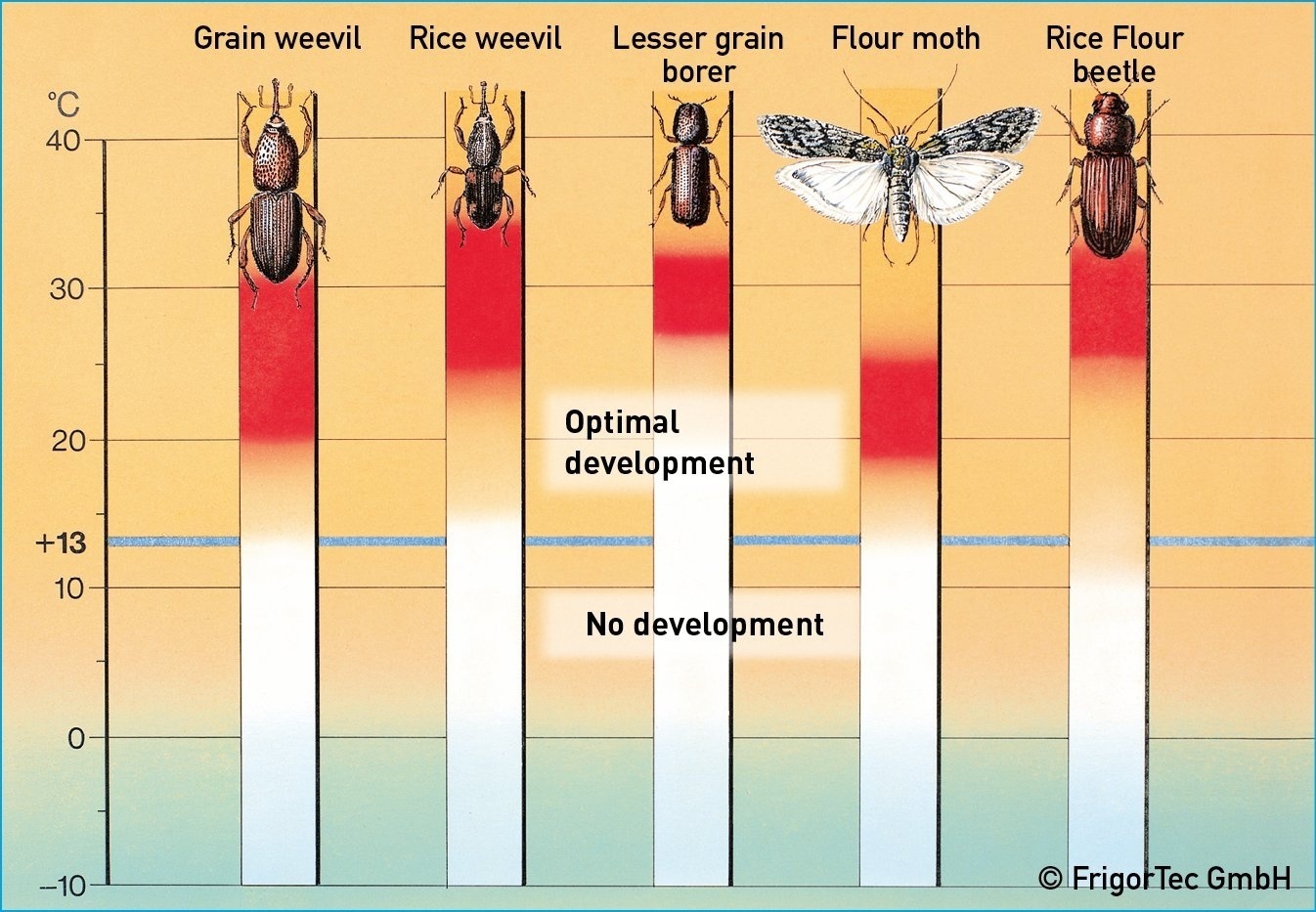

Depending on the climate zone, the grain is exposed to different types of pests. Insects are sensitive to temperature, their activity fluctuates depending on the ambient temperature. If the temperatures are too low, they become dormant: their metabolism and reproductive capacity are reduced.

Cooling slows down pests and fungi

Both insects and mould can only survive in the grain if they find suitable environmental conditions. This is where grain cooling comes in: By regulating humidity and temperature, it combats both threats at the same time. The grain moisture is usually set to 14.5%, the optimal protection temperature differs depending on the crop. Rapeseed, for example, has a relatively high specific heat development and must therefore be cooled. Below 15 °C, even cold-resistant pests start to fall into the dormancy (see figure).

A grain temperature of at most 15 °C therefore provides effective protection against insect damage: it paralyses the development and multiplication and thus prevents damage to the grain by eating and excrement.

The extraction of heat and moisture also prevents the spread of mould and the associated contamination with mycotoxins. In addition to protection against spoilage, insect damage and the spread of fungi, the cooling of the grain maintains important properties of the grain. In this way, the germ quality of grain, rice, corn, seeds and malting barley is maintained over a long period of time.

Investment in the future of food security

As the global average temperature rises, so does the risk of insect crop loss. Warm temperatures favour the high metabolisms and higher growth rates of the pest populations. Researchers therefore predict additional crop losses of 10 - 25% per 1 °C global warming.

If the average temperature rises by 2 °C, 213 million tons of maize, wheat and rice alone will be destroyed by insect pests. Especially in temperate growing areas such as Europe, North America or China, the effects of insect damage will increase dramatically with climate change. Harvesting methods such as grain cooling help to at least partially contain these losses.

Our products

More know-how articles

The best cooling strategy for your grain storage method

Grain can be cold-stored in both floor-level stores and silos. However cooling of the loose grain requires professional air distribution. The grain cooler must also be selected according to requirements. The fully automated control then frees up time for other activities.

Commissioning and maintenance of grain cooling devices

With the new fully automated controller from FrigorTec, the grain cooling unit operates fully automatically. In addition to correct commissioning and settings, careful maintenance is essential for the best possible cooling performance. We describe these and other aspects clearly in our videos.

Combining grain coolers for a flexible solution

Operators of a grain storage facility with a capacity of 76.000 tonnes are looking for a cooling solution that works independently from the weather. A combination of one permanently installed central GRANIFRIGOR™ cooler and two mobile units proves to be a flexible solution that meets all requirements.

Safe storage conditions no matter the weather

A storage facility from the 1970s was designed for ambient ventilation. The switch to a GRANIFRIGOR™ KK 280 AHY allows for precise cooling in all weather conditions. The new cooling solution also eliminates silo condensation problems and prolongs the storage duration of malting barley.

Arrange a consultation appointment

Our experts will be happy to advise you on the planning and implementation of your projects. Together we will find a perfect customised solution.

Arrange an appointment